Heat Exchange Tube ( 53 )

Heat Exchange Tube ( 53 ) Boiler Tube ( 37 )

Boiler Tube ( 37 ) Nickel Alloy Steel Pipe ( 21 )

Nickel Alloy Steel Pipe ( 21 ) Nickel Alloy Steel Tube ( 16 )

Nickel Alloy Steel Tube ( 16 ) Duplex Steel Pipe ( 10 )

Duplex Steel Pipe ( 10 ) Duplex Steel Tube ( 4 )

Duplex Steel Tube ( 4 ) Stainless Steel Pipe ( 18 )

Stainless Steel Pipe ( 18 ) Stainless Steel Tube ( 14 )

Stainless Steel Tube ( 14 ) Steel Flange ( 30 )

Steel Flange ( 30 ) Steel Fitting ( 25 )

Steel Fitting ( 25 ) Special Steel Products ( 14 )

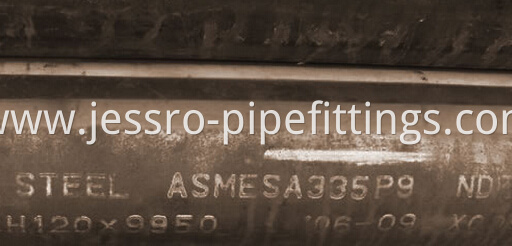

Special Steel Products ( 14 )Model No.: ASTM A335 P9 Alloy Steel Pipes

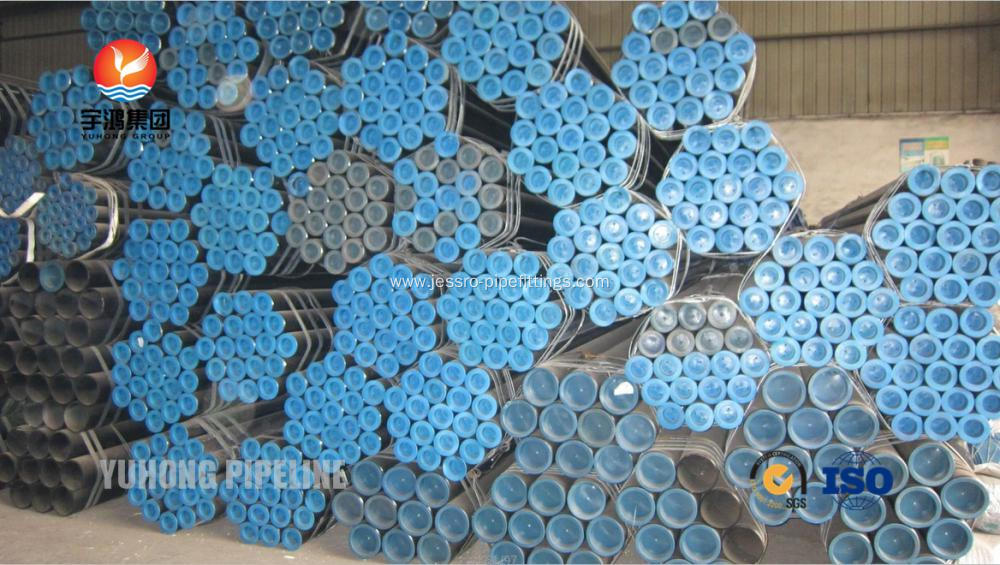

Brand: YUHONG

Packaging: Ply-wooden Case /Iron Case/ Bundle with plastic Cap

Productivity: 1500 Tons Per Month

Transportation: Ocean,Land,Air

Place of Origin: CHINA

Certificate: ISO9001-2008, API 5L, API 5CT, PED, AD-2000, EN10204-3.1B

Payment Type: T/T,L/C,D/P

Alloy steel, Alloy steel pipe, ASTM A335, ASTM A335 p9, Steel pipe, steel pipes

ASTM A335 P9 is the part of ASTM A335, The pipe shall be suitable for bending, flanging, and similar forming operations, and for fusion welding. The steel material shall conform to chemical composition, tensile property, and hardness requirements.

Each length of pipe shall be subjected to the hydrostatic test. Also, each pipe shall be examined by a non-destructive examination method in accordance to the required practices.

The different mechanical test requirements for pipes, namely, transverse or longitudinal tension test, flattening test, and hardness or bend test are presented.Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles or as requested.

Material & Manufacture

Heat Treatment

Mechanical Tests Specified

Notes for Bend Test:

Chemical Requirements of ASTM A335 P9

| Chemical elements | Data |

| UNS Designa-tion | K41545 |

| Carbon(max) | 0.15 |

| Manganese | 0.30-0.60 |

| P&S(max) | 0.025 |

| Silicon(max) | 0.50 |

| Chromium | 4.00-6.00 |

| Molybdenum | 0.45-0.65 |

| Others | - |

Mechanical Properties of ASTM A335 P9

| Properties | Data |

| Tensile strength, min,( 57018532,MPa) | 415 |

| Yield strength, min,( 57018533,MPa) | 205 |

| Elongation, min,( 57018534,%), L/T | 30/20 |

Permitted tolerance for OD

| OD | Plus tolerance(+) | Minus tolerance (-) |

| 10.29-48.3 | 0.4 | 0.4 |

| <48.3--≤114.3 | 0.79 | 0.79 |

| <114.3-≤219.1 | 1.59 | 0.79 |

| <219.1-≤323.9 | 2.38 | 0.79 |

| <323.9 | ±1% | |

Application: For manufacturing boiler, reheater, superheater, heat exchanger, condenser, etc.

Inspection items:

1. Chemical Composition

2. Mechanical Properties

3. Hardness

4. Impact Test

5. Flattening Test

6. Bending Test

7. Flaring Test

8. Flange Test

9. Drift Test

10. Hydrostatic Test

11. Eddy Current Test

12. Ultrasonic Test

13. M. P. I.

14. L. M. T.

15. Size

16. Surface Quality

17. Decarburizing Layer Depth

18. Micro Structure

19. Grain Size Analysis

20. Intercrystalline Corrosion

21. Stabilization Heat Treatment.

22. Erosion Test

Product Categories : Boiler Tube > Alloy Steel Boiler Tube