Heat Exchange Tube ( 53 )

Heat Exchange Tube ( 53 ) Boiler Tube ( 37 )

Boiler Tube ( 37 ) Nickel Alloy Steel Pipe ( 21 )

Nickel Alloy Steel Pipe ( 21 ) Nickel Alloy Steel Tube ( 16 )

Nickel Alloy Steel Tube ( 16 ) Duplex Steel Pipe ( 10 )

Duplex Steel Pipe ( 10 ) Duplex Steel Tube ( 4 )

Duplex Steel Tube ( 4 ) Stainless Steel Pipe ( 18 )

Stainless Steel Pipe ( 18 ) Stainless Steel Tube ( 14 )

Stainless Steel Tube ( 14 ) Steel Flange ( 30 )

Steel Flange ( 30 ) Steel Fitting ( 25 )

Steel Fitting ( 25 ) Special Steel Products ( 14 )

Special Steel Products ( 14 )Model No.: High Temperature Alloy Tube

Brand: YUHONG

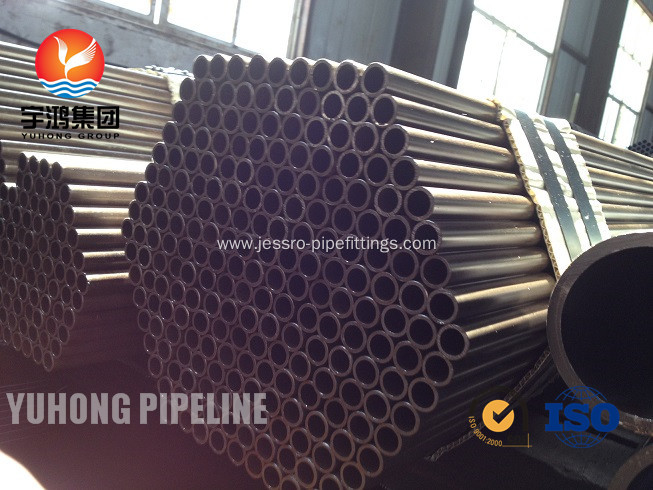

Type: Seamless

Certification: CE

Application: Gas Pipe

Section Shape: Round

Surface Treatment: Oiled

Usage: Thermal Equipment

Technique: Cold Drawn

Material: Alloy Steel

Packaging: Ply-wooden Case /Iron Case/ Bundle with plastic Cap

Productivity: 1500 Tons Per Month

Transportation: Ocean,Land,Air

Place of Origin: CHINA

Certificate: ISO9001-2008, API 5L, API 5CT, PED, AD-2000, EN10204-3.1B

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF

ASTM A213 T92 Seamless Alloy Tube

Chemical Composition(%) for ASTM A213 T92 Low Alloy Steel

| UNS Designation | K91271 |

| Carbon | 0.07–0.14 |

| Manganese | 0.7 |

| Phosphorus | 0.02 |

| Sufur | 0.01 |

| Silicon | 0.5 |

| Nickel | 0.5 |

| Chromium | 10.0–11.5 |

| Molybdenum | 0.25–0.60 |

| Vanadium | 0.15–0.30 |

| Boron | 0.0005–0.005 |

| Niobium | 0.04–0.10 |

| Nitrogen | 0.040–0.1 |

| Aluminum | 0.02 |

| Tungsten | 1.50–2.50 |

| Ti | 0.01 |

| Zr | 0.01 |

| Other Elements | Cu 0.30–1.70 |

Mechanical properties for ASTM A213 T92 Low Alloy Steel

| Tensile strength(min) | 620Mpa |

| Yield strength(min) | 440Mpa |

| Elongation | 20% |

| Hardness, HB | 250max |

Permitted tolerance for OD

| OD | Plus tolerance(+) | Minus tolerance (-) |

| 10.29-48.3 | 0.4 | 0.4 |

| <48.3--≤114.3 | 0.79 | 0.79 |

| <114.3-≤219.1 | 1.59 | 0.79 |

| <219.1-≤323.9 | 2.38 | 0.79 |

| <323.9 | ±1% | |

Wall thickness is average wall or according to ASME SA530.

Notes for Bend Test:

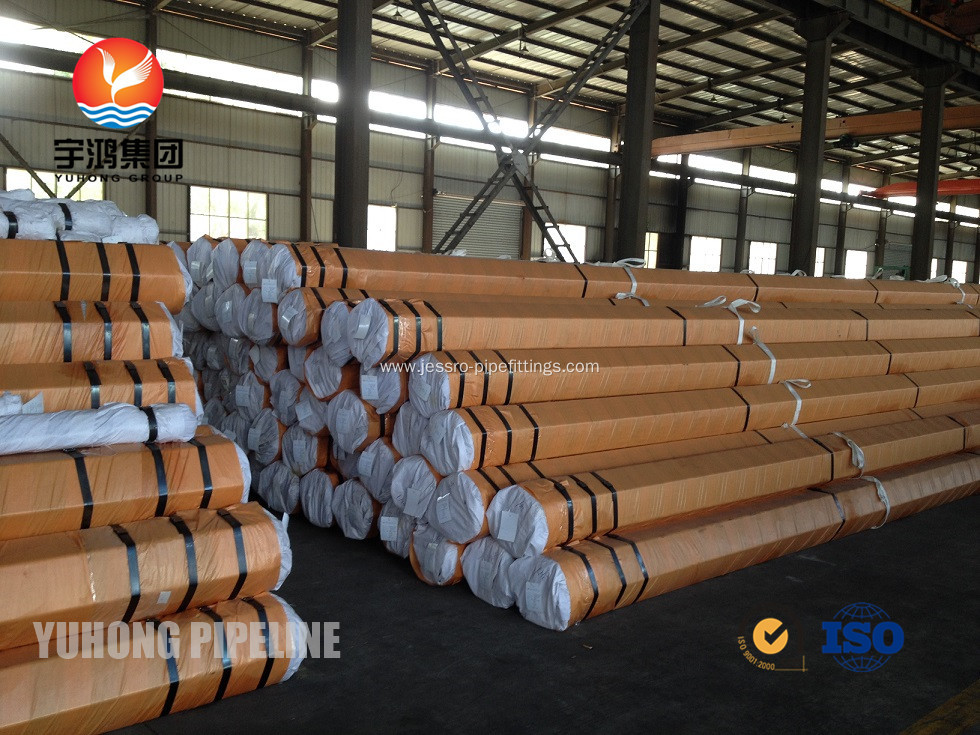

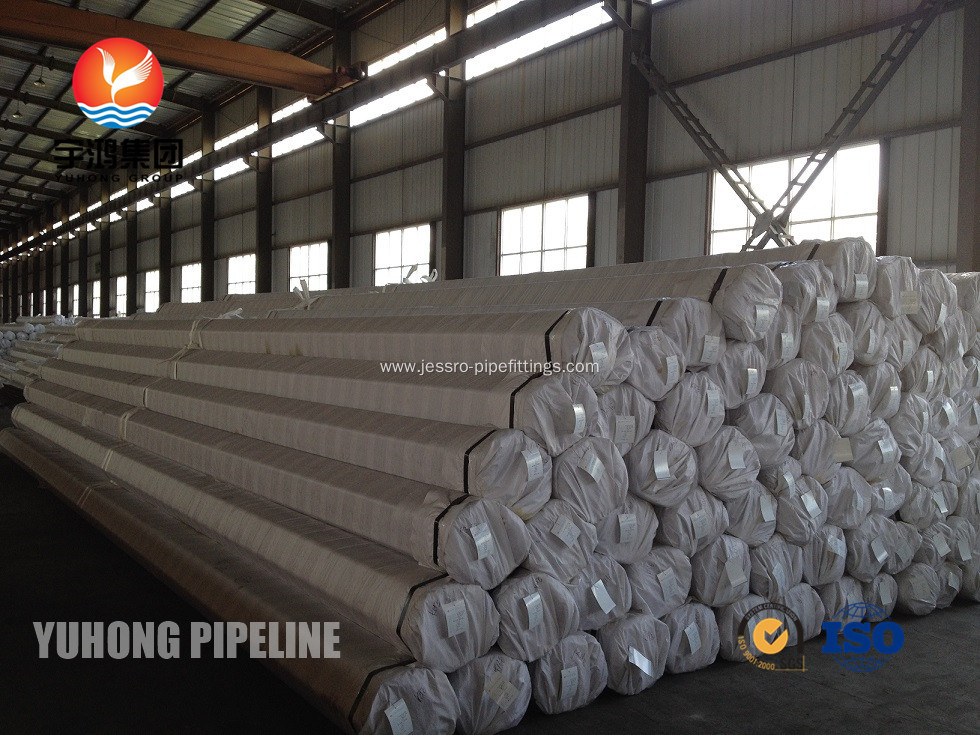

Packing:

Delivery:

Pipes are supplied in hexagonal bundles or round bundles tied with steel strip.

Weight of bundle – up to 5000 kg upon request of customer.

Each bundle is furnished with three tags.

ASTM A213 Standard Scope

1.1 This specification covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes, designated Grades T91, TP304, etc. These steels are listed in Tables 1 and 2.

1.2 Grades containing the letter, H, in their designation, have requirements different from those of similar grades not containing the letter, H. These different requirements provide higher creep-rupture strength than normally achievable in similar grades without these different requirements.

1.3 The tubing sizes and thicknesses usually furnished to this specification are 1/8 in. [3.2 mm] in inside diameter to 5 in. [127 mm] in outside diameter and 0.015 to 0.500 in. [0.4 to 12.7 mm], inclusive, in minimum wall thickness or, if specified in the order, average wall thickness. Tubing having other diameters may be furnished, provided such tubes comply with all other requirements of this specification.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless the [M" designation of this specification is specified in the order.

TABLE 1 Chemical Composition Limits, %A, for Low Alloy SteelA Maximum, unless range or minimum is indicated. Where ellipses (-) appear in this table, there is no requirement, and analysis for the element need not be determined or reported.

B It is permissible to order T2 and T12 with a sulfur content of 0.045 max. See 16.3.

C Alternatively, in lieu of this ratio minimum, the material shall have a minimum hardness of 275 HV in the hardened condition, defined as after austenitizing and cooling to room temperature but prior to tempering. Hardness testing shall be performed at mid-thickness of the product. Hardness test frequency shall be two samples of product per heat treatment lot and the hardness testing results shall be reported on the material test report.

YUHONG GROUP deal with Austenitic Stainless Steel, Nickel Alloy Steel (Hastelloy , Monel, Inconel, Incoloy) seamless and welded pipe and tube already more than 25 years, every year sell more than 80000 tons of steel pipe and tube. Our client already cover more than 45 countries, Like Italy, UK, Gernmany, USA, Canada, Chile, Colombia, Saudi Arabia, Russia, Korea, Singapore, Austrial, Poland, France , ....And our group branch company and factory have been already approved by : ABS, DNV, GL, BV, PED 97/23/EC, AD2000-WO, GOST9941-81, CCS, TS, CNNC, ISO9001-2008, ISO 14001-2004.

Product Categories : Boiler Tube > Alloy Steel Boiler Tube