Heat Exchange Tube ( 53 )

Heat Exchange Tube ( 53 ) Boiler Tube ( 37 )

Boiler Tube ( 37 ) Nickel Alloy Steel Pipe ( 21 )

Nickel Alloy Steel Pipe ( 21 ) Nickel Alloy Steel Tube ( 16 )

Nickel Alloy Steel Tube ( 16 ) Duplex Steel Pipe ( 10 )

Duplex Steel Pipe ( 10 ) Duplex Steel Tube ( 4 )

Duplex Steel Tube ( 4 ) Stainless Steel Pipe ( 18 )

Stainless Steel Pipe ( 18 ) Stainless Steel Tube ( 14 )

Stainless Steel Tube ( 14 ) Steel Flange ( 30 )

Steel Flange ( 30 ) Steel Fitting ( 25 )

Steel Fitting ( 25 ) Special Steel Products ( 14 )

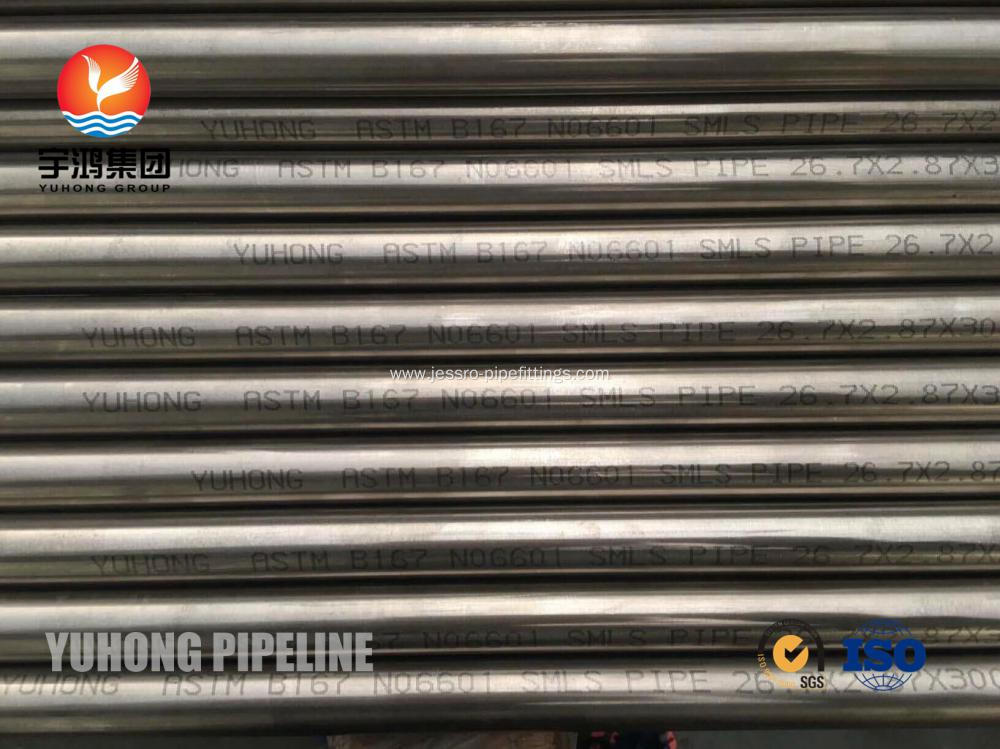

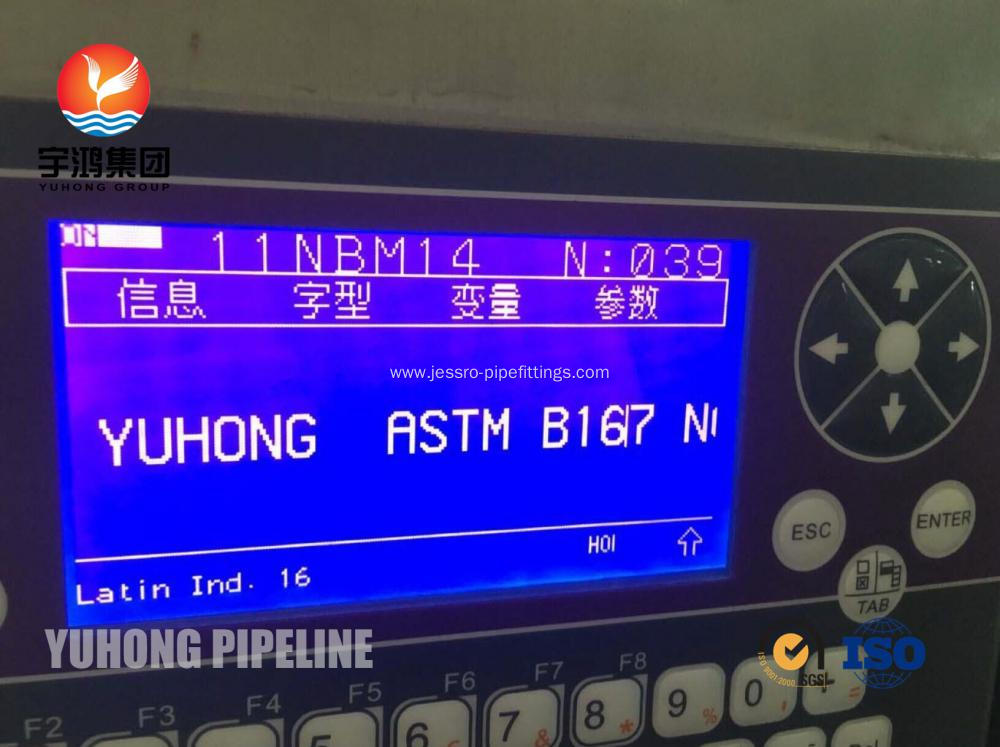

Special Steel Products ( 14 )Model No.: Inconel tube

Brand: YUHONG

Type: Seamless

Certification: CE

Application: Drill Pipe

Section Shape: Round

Surface Treatment: Polished

Usage: Thermal Equipment

Technique: Cold Rolled

Material: Alloy Steel

Packaging: Plywood Case Packing

Productivity: 300 Tons Per Month

Transportation: Ocean,Land,Air

Place of Origin: CHINA

Certificate: TUV, API, PED, ISO

Payment Type: L/C,T/T,D/P,Western Union

Incoterm: FOB,CFR,CIF

| Standard: | ASME SB163 , SB167 | Grade: | INCONEL 601,EN 2.4851, UNS N06601 ,Werkstoff 2.4851 |

|---|---|---|---|

| Size: | OD:3MM TO 530MM ,WT:0.2MM TO 60MM, L:MAX 50M | PACKING: | Ply-wooden Case Or Iron Case |

Seamless Inconel 601 Tubing Pickled Anneales Bevel End High Strength

Inconel 601 is a nickel-chromium alloy, that is highly resistant to oxidation through 2200°F. 601 alloy develops a tightly adherent oxide scale which resists spalling even under severe thermal cycling. The alloy has good high temperature strength, and retains its ductility after long service exposure. 601 alloy has good hot corrosion resistance under oxidizing conditions. 601 alloy is not suggested for use in strongly reducing, sulfur bearing environments.

For maximum oxidation resistance, 601 alloy should be welded with matching composition 601 alloy GTAW wire. The weld fillers developed for RA 602 CA can also provide a weld which is stronger and more oxidation resistant than the 601 alloy base metal. 601 alloy is more difficult to machine than 304 stainless steel. Its machinability rating is 15-21% relative to AISI B1112 steel.

| Ni | Cr | Al | C | Mn | Cu | Si | S | Fe | |

|---|---|---|---|---|---|---|---|---|---|

| MIN | 58.00 | 21.00 | 1.00 | -- | -- | -- | -- | -- | -- |

| MAX | 63.00 | 25.00 | 1.70 | 0.10 | 1.00 | 1.00 | 0.50 | 0.015 | Balance |

*ASTM specification 0.20 max C.

601 Coil, 601 Pipe, 601 Plate, 601 Sheet

Alloy 601, Inconel® 601, Nickel 601

Density: 0.293 lb/in3

Melting Point: 2375 - 2495°F

| Temperature, °F | 70 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 |

| Coefficient* of Thermal Expansion, in/in°F x 10-6 | - | 8.5 | 8.9 | 9.2 | 9.5 | 9.8 | 10.2 |

| Thermal Conductivity Btu • ft/ft2 • hr • °F | 6.5 | 11.6 | 12.7 | 13.7 | 14.8 | 15.8 | 16.9 |

| Modulus of Elasticity, Dynamic psi x 106 | 29.95 | 25.43 | 24.12 | 22.48 | 20.54 | 18.43 | 16.20 |

* 70°F to indicated temperature.

Short-Time Elevated Temperature Tensile Properties

| Temperature,°F | 70 | 1000 | 1200 | 1400 | 1600 |

| Ultimate Tensile Strength, ksi | 100 | 90 | 60 | 34 | 18 |

| 0.2% Yield Strength, ksi | 54 | 48 | 41 | 26 | 15 |

| Elongation, % | 45 | 44 | 45 | 70 | 120 |

Typical Creep - Rupture Properties

| Temperature, °F | 1400 | 1600 | 1800 | 2000 |

| Minimum Creep 0.0001%/Hour, ksi | 4.1 | 2.0 | 0.76 | 0.43 |

| 10,000 Hour Rupture Strength, ksi | 6.2 | 2.6 | 1.2 | 0.62* |

* Extrapolated

Product Categories : Nickel Alloy Steel Tube > Inconel Tube