Heat Exchange Tube ( 53 )

Heat Exchange Tube ( 53 ) Boiler Tube ( 37 )

Boiler Tube ( 37 ) Nickel Alloy Steel Pipe ( 21 )

Nickel Alloy Steel Pipe ( 21 ) Nickel Alloy Steel Tube ( 16 )

Nickel Alloy Steel Tube ( 16 ) Duplex Steel Pipe ( 10 )

Duplex Steel Pipe ( 10 ) Duplex Steel Tube ( 4 )

Duplex Steel Tube ( 4 ) Stainless Steel Pipe ( 18 )

Stainless Steel Pipe ( 18 ) Stainless Steel Tube ( 14 )

Stainless Steel Tube ( 14 ) Steel Flange ( 30 )

Steel Flange ( 30 ) Steel Fitting ( 25 )

Steel Fitting ( 25 ) Special Steel Products ( 14 )

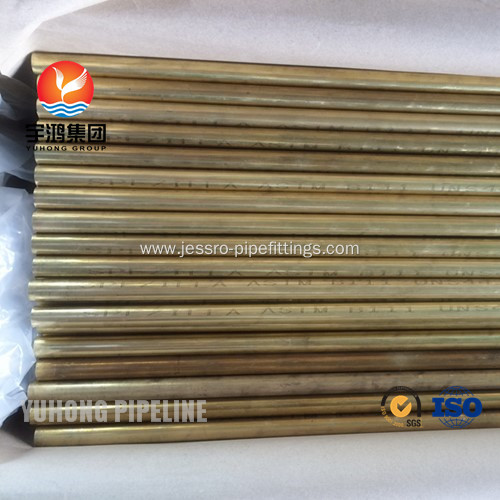

Special Steel Products ( 14 )Model No.: Copper Tube

Brand: YUHONG

Type: Straight Copper Pipe

Shape: Round

Application: Oil Cooler Pipe

Alloy: Alloy

Certification: ISO

Grade: H70

State: Soft

Color: Yellow

Packaging: Wooden Case Packing

Productivity: 500 Tons Per Month

Transportation: Ocean,Land,Air

Place of Origin: CHINA

Certificate: ASTM B111 ASTM B28

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF

Length Range: < 15000 mm

Copper Nickel Pipe Standards and Composition

| Trade Name | UNS | Copper Nickel Industry Specifications | Chemical Composition | Min. Tensile (KSI) | Min. Yield (KSI) | Elongation % |

| CuNi 90/10 | UNS C70600 UNS C70620 | ASME SB111, SB171, SB359, SB395, SB466, SB467, SB543 ASTM B111, B122, B151, B171, B359, B395, B432, B466, B467, B543, B608 DIN 2.0872 MIL C-15726, T-15005, T-16420, T-22214 SAE J461, J463 | Cu 88.6 min Pb. 05 max* Fe 1.8 max Zn 1 max* Ni 9-11 max Mn 1.0 max | 38 | 15 | 30 |

| CuNi 90/10 | UNS C70600 | EEMUA 144 90/10, 145 90/10, 14 90/1 | Cu rem. Pb. 01 max Fe 1.5-2.0 Zn 0.2 max P 0.2 max S 0.2 max Ni 10-11 Mn 0.5-1.0 | 40 | 15 | 30 |

| CuNi 70/30 | UNS C71500 UNS C71520 | ASME SB111, SB171, SB359, SB395, SB466, SB467, SB543 ASTM B111, B122, B151, B171, B359, B395, B432, B467, B543, B552, B608, F467, F468 DIN 2.0882 MIL C-15726, T-15005, T-16420, T-22214 SAE J461, J463 | Cu rem (65.0 min) Pb. 05 max* Fe 0.4-1.0 Zn 1 max* Ni 29-33 Mn 1 max | 52 | 18 | 45 |

| CuNi 70/30 | UNS C71640 | ASTM B111, B543, B552 | Cu rem Pb. 05 max* Fe 1.7-2.3 Zn 1 max* Ni 29-32 Mn 1.5-2.5 | 63 | 25 | - |

| Copper Nickel Pipes and Tubes | Cupro Nickel Pipes and Tubes |  |

Cupro Nickel Tubes 90/10 for Heat Exchangers & Condensers

These Cupro Nickel tubes & pipes for Heat Exchangers & Condensers are very important for all Industrial fields. The company has experience in these areas and is able to supply these tubes in accordance with most international standards and special customer requirements.

Cupro Nickel Tubes 90/10 for Automobile Industries

The Move To Copper-Nickel Tubing

Copper had been proved since the early days to have many good attributes. It was easy to bend and had very high corrosion resistance, but there was concern about its low corrosion-fatigue strength. When copper-nickel was introduced, it displayed corrosion resistance similar to copper, higher general strength and better fatigue strength. Good formability allows ease of flaring and bending, and although the metal cost is greater than that of steel alternatives, copper-nickel is very attractive in view of its extra life, trouble-free installation and safety/reliability characteristics.

Properties of Copper-Nickel Brake Tubing

The copper-nickel alloy used for brake tubing typically contains 10% nickel, with iron and manganese additions of 1.4% and 0.8% respectively. The product conforms to ASTM B466 (American Society for Testing and Materials), which specifies dimensions, tensile strength and yield strength. Formability and internal cleanliness conform to specifications SAE J527, ASTM A254 and SMMT C5B (Society of Motor Manufacturers and Traders). Also, the alloy meets the requirements for pressure containment, fabrication and corrosion resistance for ISO 4038 (International Standards Organization) and SAE J1047.

Product Categories : Heat Exchange Tube > Copper Nickel Alloy Tube