Heat Exchange Tube ( 53 )

Heat Exchange Tube ( 53 ) Boiler Tube ( 37 )

Boiler Tube ( 37 ) Nickel Alloy Steel Pipe ( 21 )

Nickel Alloy Steel Pipe ( 21 ) Nickel Alloy Steel Tube ( 16 )

Nickel Alloy Steel Tube ( 16 ) Duplex Steel Pipe ( 10 )

Duplex Steel Pipe ( 10 ) Duplex Steel Tube ( 4 )

Duplex Steel Tube ( 4 ) Stainless Steel Pipe ( 18 )

Stainless Steel Pipe ( 18 ) Stainless Steel Tube ( 14 )

Stainless Steel Tube ( 14 ) Steel Flange ( 30 )

Steel Flange ( 30 ) Steel Fitting ( 25 )

Steel Fitting ( 25 ) Special Steel Products ( 14 )

Special Steel Products ( 14 )Model No.: Heat Exchanger Tube

Brand: YUHONG

Type: Seamless

Application: Boiler Pipe

Section Shape: Round

Usage: Thermal Equipment

Technique: Cold Rolled

Material: Stainless Steel

Packaging: Ply-wooden Case /Iron Case/ Bundle with plastic Cap

Productivity: 800 Tons Per Month

Transportation: Ocean,Land,Air

Place of Origin: CHINA

Certificate: TUV, API, PED, ISO, BV, SGS, GL, DNV

Payment Type: L/C,T/T,Money Gram,Western Union

Incoterm: FOB,CFR,CIF

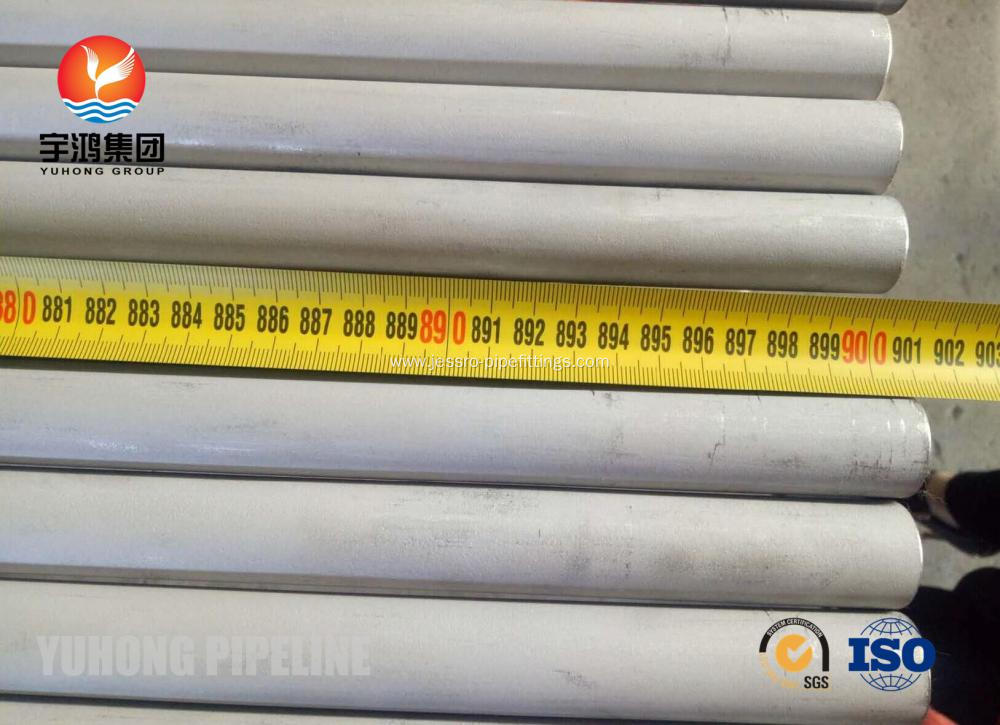

Stainless Steel Seamless Tube ASTM A213 TP321 / TP321H FOR HEAT EXCHANGER TUBE 25MM X 2MM X 9000MM , HYDROSTATIC TEST AND EDDY CURRENT TEST

YUHONG GROUP deal with Austenitic Stainless Steel, Nickel Alloy Steel(Hastelloy , Monel, Inconel, Incoloy ) seamless and welded pipe and tube already more than 25 years, every year sell more than 80000 tons of steel pipe and tube. Our client already cover more than 45 countries, Like Italy, UK, Gernmany, USA, Canada, Chile, Colombia, Saudi Arabia, Russia, Korea, Singapore, Austrial, Poland, France , ....And our group branch company and factory have been already approved by :ABS, DNV, GL, BV, PED 97/23/EC, AD2000-WO, GOST9941-81, CCS, TS, CNNC, ISO9001-2008, ISO 14001-2004.

Material Grade:

| American Standard | Austenitic Steel: TP304,TP304L,TP304H, TP304N, TP310S,TP316,TP316L,TP316Ti,TP316H, TP317,TP317L, TP321, TP321H,TP347, TP347H,904L- Duplex Steel : S32101,S32205,S31803,S32304,S32750, S32760 Nickel Alloy: UNS NO8800, NO8811, NO8825, NO8810, NO718, NO690, NO6625, NO6600, NO4400 Others:TP405,TP409, TP410, TP430, TP439,... |

| Europen Standard | 1.4301,1.4307,1.4948,1.4541,1.4878,1.4550,1.4401,1.4404,1.4571,1.4438, 1.4841,1.4845,1.4539,1.4162, 1.4462, 1.4362, 1.4410, 1.4501 |

| Russia Standard | 08Х17Т,08Х13,12Х13,12Х17,15Х25Т,04Х18Н10,08Х20Н14С2, 08Х18Н12Б,10Х17Н13М2Т,10Х23Н18,08Х18Н10,08Х18Н10Т, 08Х18Н12Т,08Х17Н15М3Т,12Х18Н10Т,12Х18Н12Т,12Х18Н9, 17Х18Н9, 08Х22Н6Т, 06ХН28МДТ |

| Tube Sizes for Heat Exchangers & Condensers & Boiler | |||||||||

| Outside Diameter | BWG | ||||||||

| 25 | 22 | 20 | 18 | 16 | 14 | 12 | 10 | ||

| Wall Thickness mm | |||||||||

| 0.508 | 0.71 | 0.89 | 1.24 | 1.65 | 2.11 | 2.77 | 3.40 | ||

| mm | inch | Weight kg/m | |||||||

| 6.35 | 1/4 | 0.081 | 0.109 | 0.133 | 0.174 | 0.212 | |||

| 9.53 | 3/8 | 0.126 | 0.157 | 0.193 | 0.257 | 0.356 | 0.429 | ||

| 12.7 | 1/2 | 0.214 | 0.263 | 0.356 | 0.457 | 0.612 | 0.754 | ||

| 15.88 | 5/8 | 0.271 | 0.334 | 0.455 | 0.588 | 0.796 | 0.995 | ||

| 19.05 | 3/4 | 0.327 | 0.405 | 0.553 | 0.729 | 0.895 | 1.236 | ||

| 25.4 | 1 | 0.44 | 0.546 | 0.75 | 0.981 | 1.234 | 1.574 | 2.05 | |

| 31.75 | 1 1/4 | 0.554 | 0.688 | 0.947 | 1.244 | 1.574 | 2.014 | 2.641 | |

| 38.1 | 1 1/2 | 0.667 | 0.832 | 1.144 | 1.514 | 1.904 | 2.454 | 3.233 | |

| 44.5 | 1 3/4 | 1.342 | 1.774 | 2.244 | 2.894 | 3.5 | |||

| 50.8 | 2 | 1.549 | 2.034 | 2.574 | 3.334 | 4.03 | |||

| 63.5 | 2 1/2 | 1.949 | 2.554 | 3.244 | 4.214 | 5.13 | |||

| 76.2 | 3 | 2.345 | 3.084 | 3.914 | 5.094 | 6.19 | |||

| 88.9 | 3 1/2 | 2.729 | 3.609 | 4.584 | 5.974 | 7.27 | |||

| 101.6 | 4 | 4.134 | 5.254 | 6.854 | 8.35 | ||||

| 114.3 | 4 1/2 | 4.654 | 5.924 | 7.734 | 9.43 | ||||

| Form of Tube: Straight & U-bend & Finned & Coiled | |||||||||

| Stainless Steel Tube: A/SA213, A/SA249, A/SA268, A/SA269, A/SA789, EN10216-5, A/SA688, B/SB163, JIS-G3463, GOST9941-81. | |||||||||

| Carbon &Alloy Steel Tube: A/SA178, A/SA179, A/SA192,A/SA209, A/SA210, A/SA213 | |||||||||

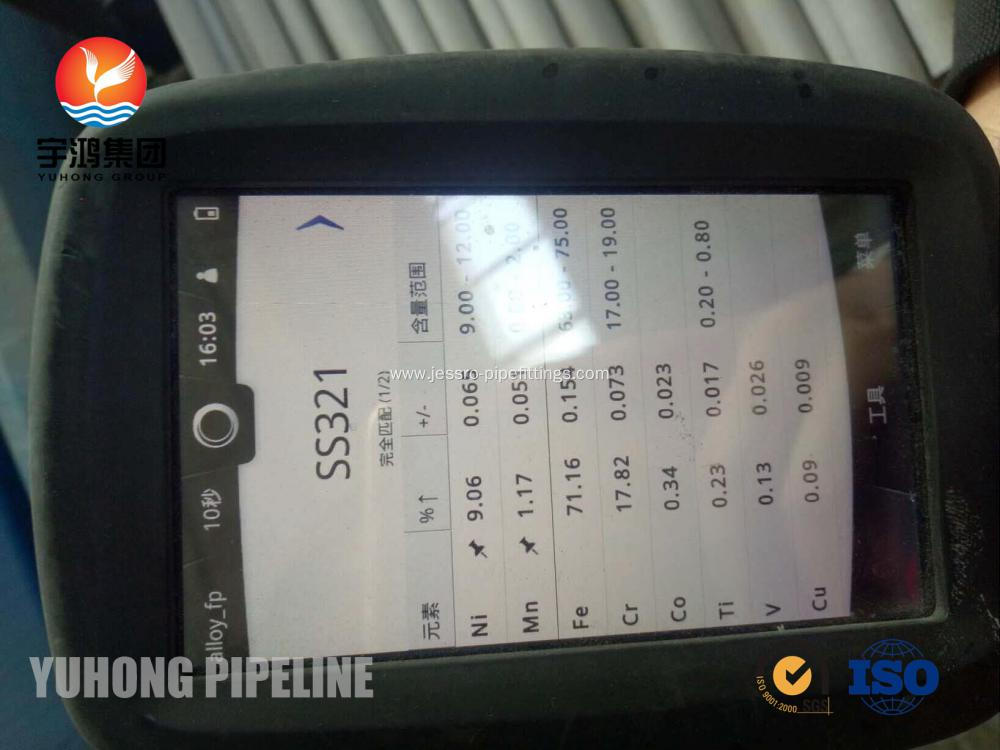

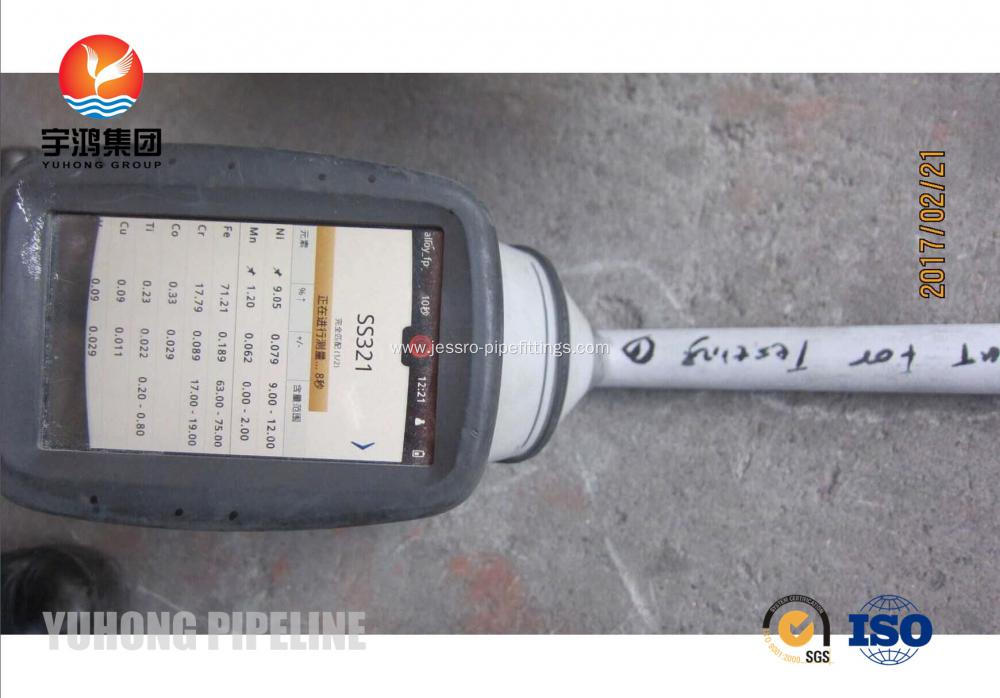

Some of the quality tests carried out by us includes:

| Corrosion Test | Conducted only when specially requested by the client |

| Chemical Analysis | Test done as per required quality standards |

| Destructive / Mechanical Testing | Tensile | Hardness | Flattening | Flare | Flange |

| Reverse-bend and Re. flat tests | Carried out in full compliance with relevant standards & ASTM A-450 and A-530 norms, which ensures trouble-free expansion, welding & use at customers end |

| Eddy Current Testing | Done to detect homogeneities in subsurface by using Digital Flaw-mark Testing System |

| Hydrostatic Testing | 100% Hydrostatic Testing carried out according to ASTM-A 450 norms for checking tube leakage, and biggest pressure we can support 20Mpa/7s . |

| Air Under Pressure Test | To check any evidence of air leakage |

| Visual Inspection | After passivation, every single length of tubes & pipes is subjected to thorough visual inspection by trained staff for detecting surface flaws & other imperfections |

Supplementary Testing : Apart from the above mentioned tests, we also carry out on the manufactured products supplementary testing. The tests conducted under this include:

|

|

|

YUHONG GROUP is one of the largest Procurement Engineering and Contracting Group companies in China. Our group branch company and factory have been already approved by : ABS, DNV, GL, BV, PED 97/23/EC, AD2000-WO, GOST9941-81, CCS, TS, CNNC, ISO9001-2008, ISO 14001-2004. Yuhong Holding Group has expanded its field of activit...

Product Categories : Heat Exchange Tube > Stainless Steel Heat Exchanger Tube